Behind The Design – Atech Composites

Atech Composites lends its global-leading expertise in advanced composites to every Horizon yacht on the water.

Welcome to Atech Composites, the Horizon Group’s dedicated composite manufacturing facility. Atech’s immersive showroom is an invitation to step into the world of yacht building and experience firsthand how the company works its magic to create cutting-edge components.

An industry leader in composite yacht building, Horizon leverages advanced technology to craft high-strength, lightweight, and high-quality yacht components.

Atech’s showroom can be described as a “mini museum of yacht manufacturing.” As you enter this exhibition space, you embark on a sensory journey that includes interactive visuals, sounds, hands-on activities, and engaging guided tours that take you through the entire process of creating a luxury yacht. From the advantages of composite materials to precision molds and patented vacuum infusion technology, all aspects of the manufacturing process are on display.

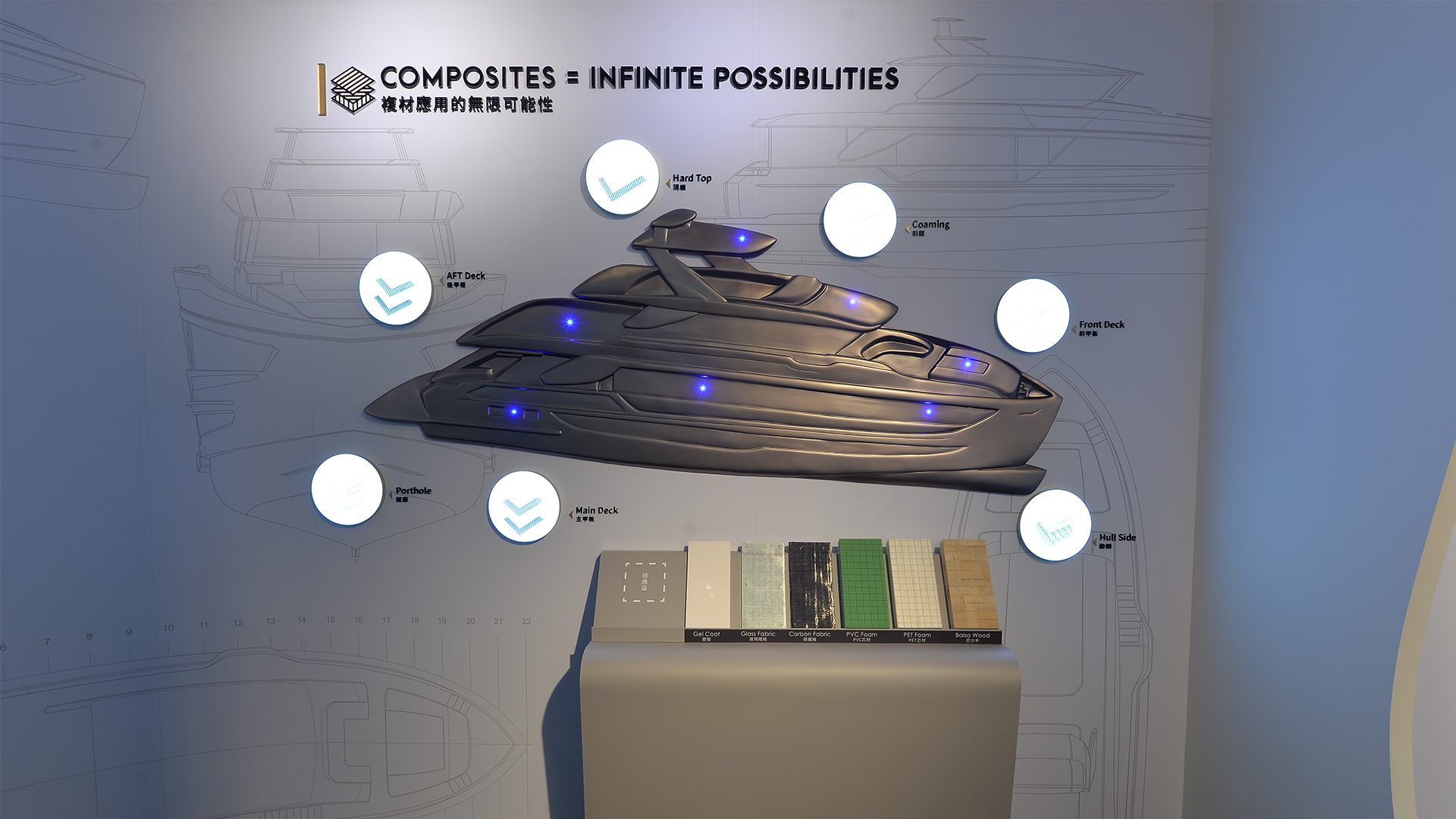

Your journey begins with the “Why Composites?” and “Composites = Infinite Possibilities” areas, where you will discover the advantages of composites over traditional metals and learn how these materials are used throughout a yacht, from the hull to the deck, and how they contribute to a safer, more comfortable, and high-performance cruising experience.

Next, the “3D Profile Measurement” area highlights the importance of precision molds in creating composite components. This section showcases how Horizon verifies precise mold dimensions for accuracy by using 3D Optical Coordinate Measuring System and Reality Capture technologies. This meticulous attention to detail is crucial for high-quality production that meets the company’s exacting standards.

Additionally, Reality Capture is applied not only prior to production to assess mold dimensions but also during the manufacturing process to ensure proper structural positioning and post-production to confirm that the finished product aligns with the design specifications.

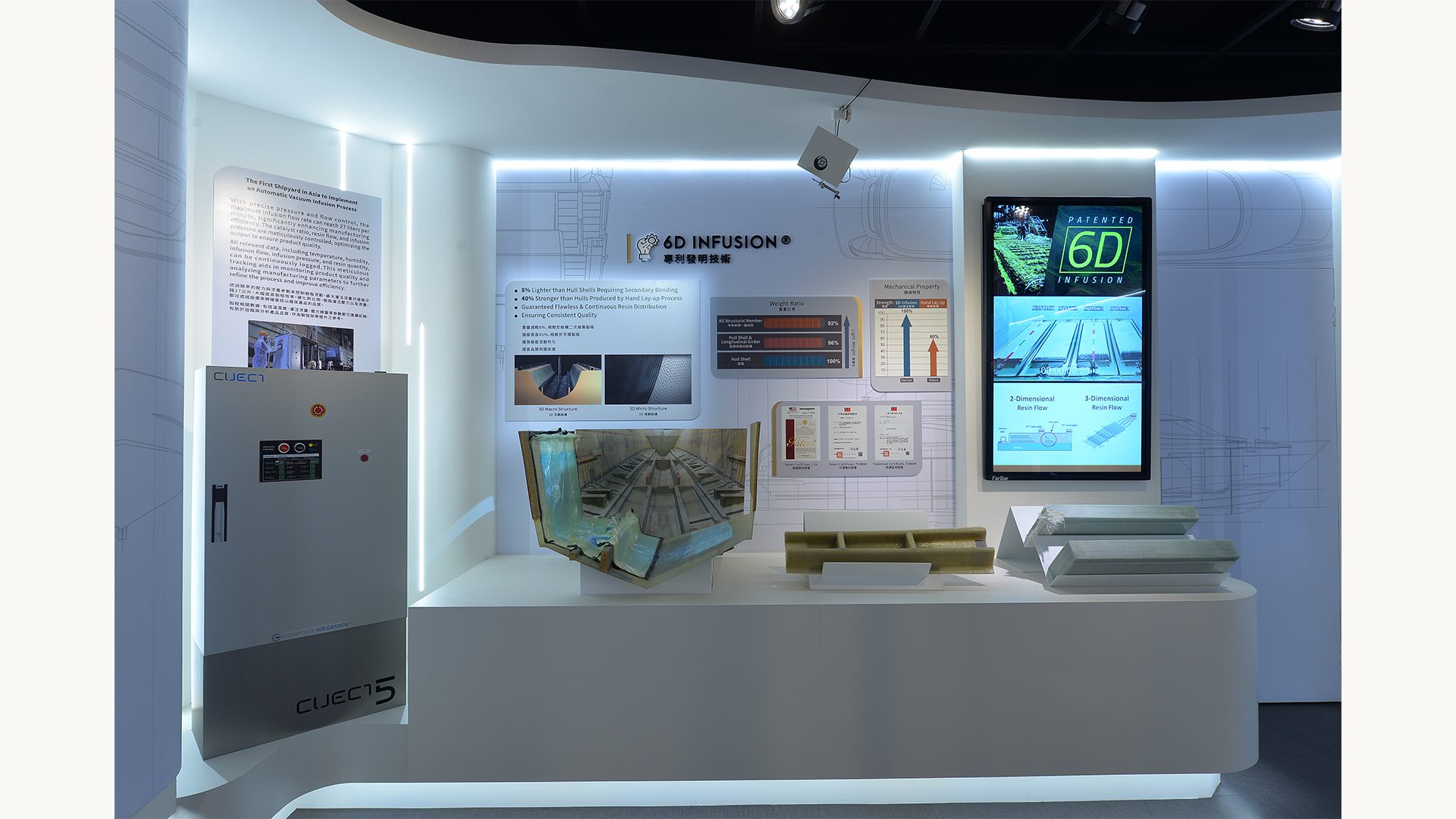

Moving on to the production process, the “Vacuum Infusion” and “6D Infusion” areas present Horizon’s patented vacuum infusion technology for hull manufacturing. A scaled-down version of the process demonstrates how lightweight, high-strength hulls are created. Here, you get an up-close look at hulls covered with vacuum materials, see how a vacuum is formed within the bag, observe resin flowing through laminates, and examine the quality of hulls infused with longitudinal girders and transverse frames in a single process.

At this stage, you may be wondering how resin gets evenly distributed throughout the hull, particularly in the typically thick laminates at the bottom. The answer lies in the use of 3D glass fabrics in targeted areas. These fabrics allow resin to flow in three directions, promoting uniform distribution. Central to this process is Horizon’s 6D Infusion technology, which produces lighter, stronger, and ultra-high-quality hulls. You can easily compare the superior quality of products made with 3D glass to those made with standard 2D glass fabrics by examining the specimens on display.

Once production wraps up, the focus shifts to quality assurance—a crucial step in the journey of every yacht. Enter the “Non-Destructive Testing” area, where aerospace-grade inspection technologies such as Active Infrared Thermography and Shearography come into the spotlight. Each yacht component’s internal quality and structural integrity are inspected using these advanced techniques to maintain the company’s strict quality controls.

Since 2012, Horizon has championed non-destructive testing to verify that every yacht meets rigorous quality standards before delivery. In fact, it stands out as the only shipyard in the global yacht-building industry equipped with such advanced inspection technology. This commitment to excellence not only preserves the craftsmanship but also guarantees that each yacht is ready to navigate the open waters with confidence.

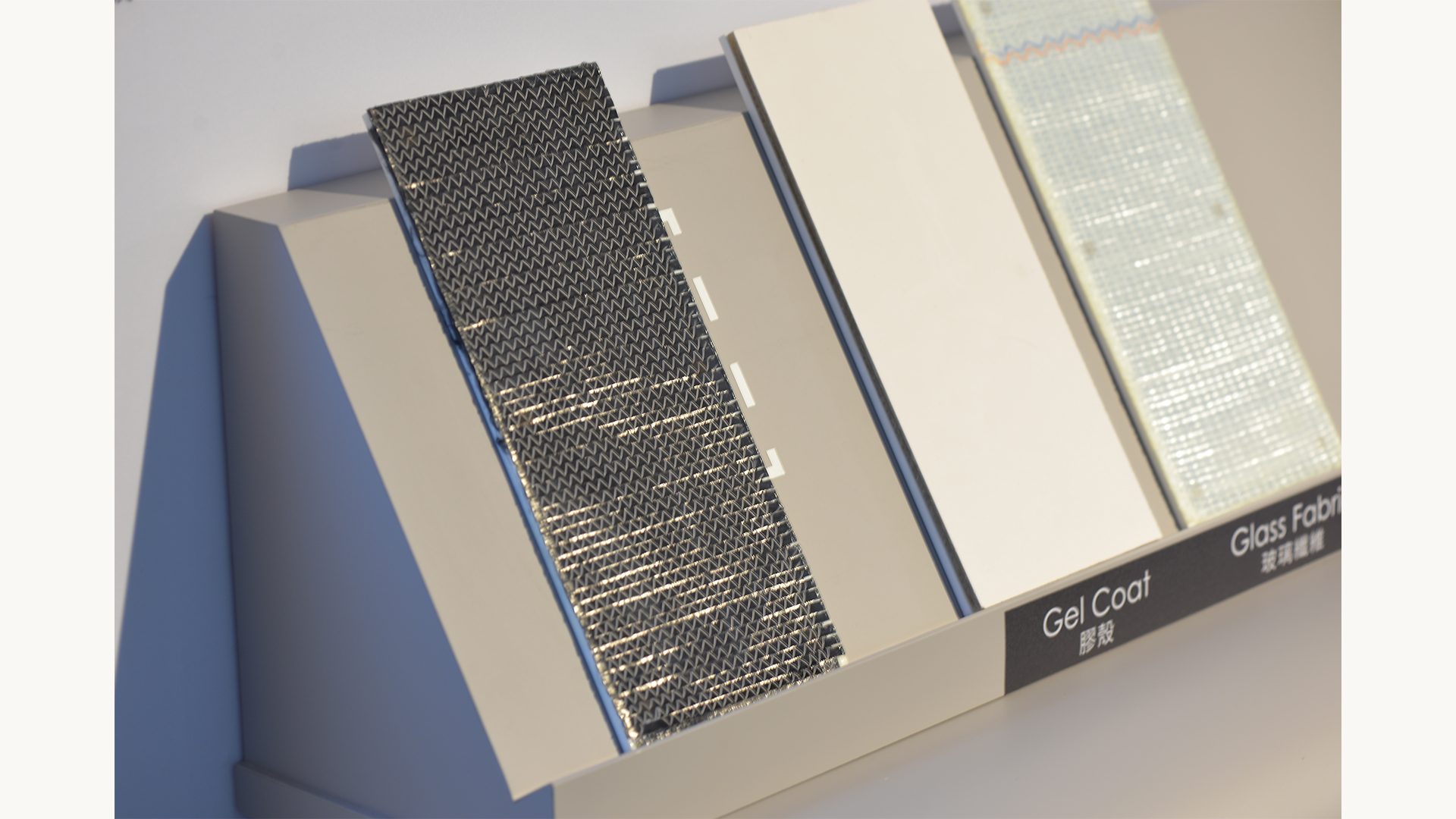

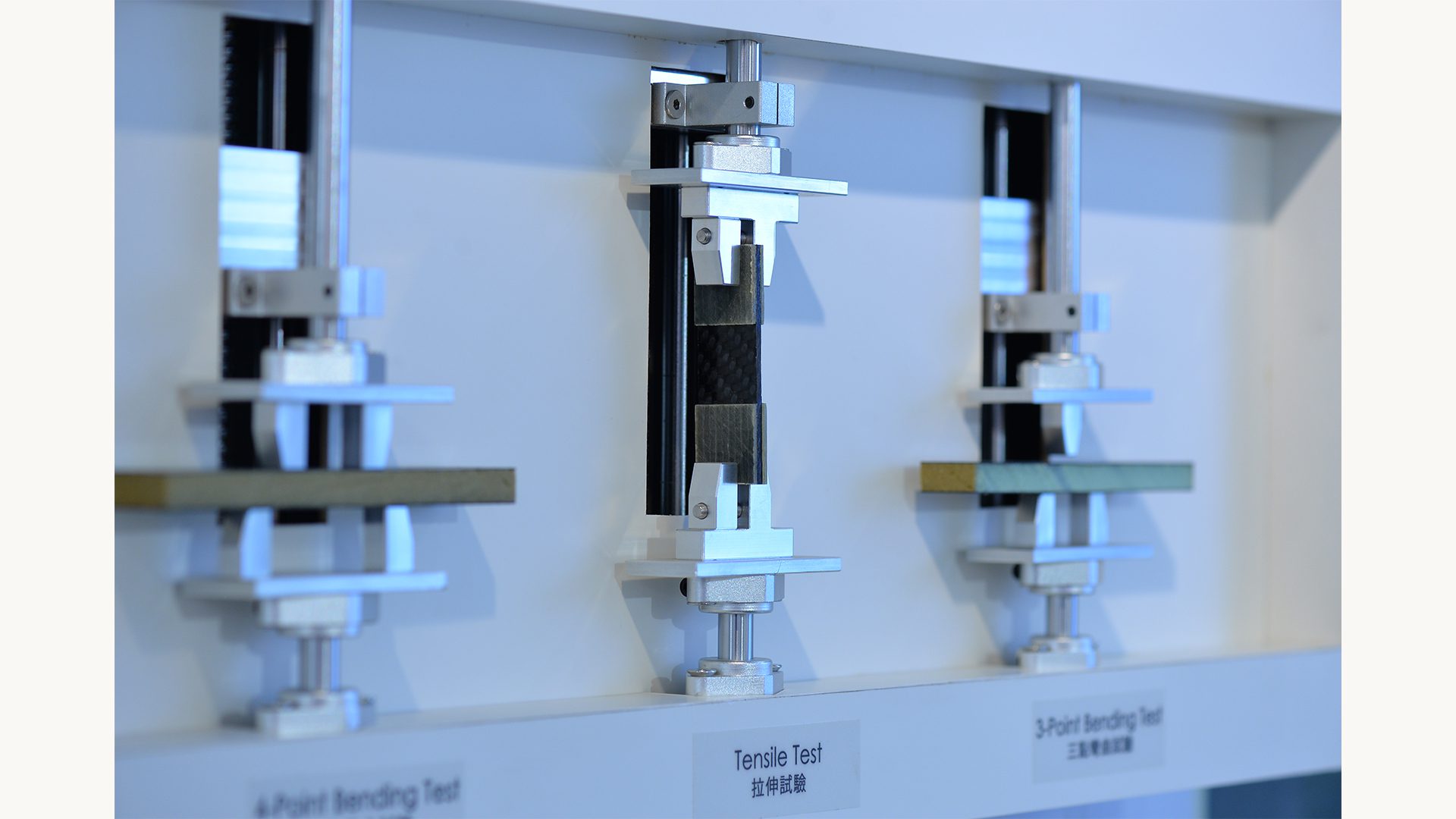

The tour doesn’t stop there. Additional showroom topics, such as “Why Materials Testing Matters?”, “Cosmetic Materials,” “Resin,” “Fabrics,” and “Core & Sandwich Structure,” invite you to delve into the unique characteristics of each material.

Interactive experiences abound, illustrating the importance of selecting the right materials for yacht construction. For instance, you can step onto three different composite panels laid out on the showroom floor, simulating the sensation of walking on a yacht deck. As you traverse these panels, you will immediately notice the differences in stiffness and stability offered by various material combinations. This hands-on experience vividly contrasts single-layer composites with sandwich structures, a key technology in reducing hull weight.

If you have the chance to visit Horizon Yachts in Taiwan, don’t miss the opportunity to explore yacht-building technology at Atech’s showroom. This is more than just an outing—it’s an invitation to witness firsthand how innovative engineering and design come together to create the yacht of your dreams. Engage with interactive displays, experience the latest innovations, and gain insights into the craftsmanship that defines each Horizon masterpiece.